PHEXPAK Packaged Plate Heat Exchangers

FlexEJ’s high-quality Packaged Plate Heat Exchangers are designed and built in the UK by FlexEJ.

24hr Shipping

On all stock items ordered.

Mon-Thur by 2pm, 10am Fridays

Design & Manufacturing

Full in-house design & manufacture to EN / ASME / PED.

ISO14001 Accreditation

FlexEJ has an accredited Environmental Management System.

Packaged Plate Heat Exchangers

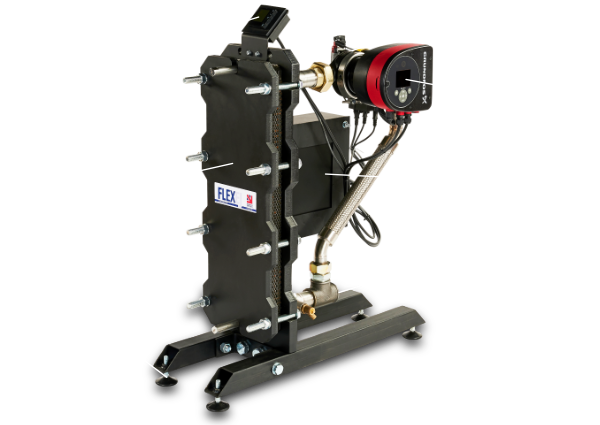

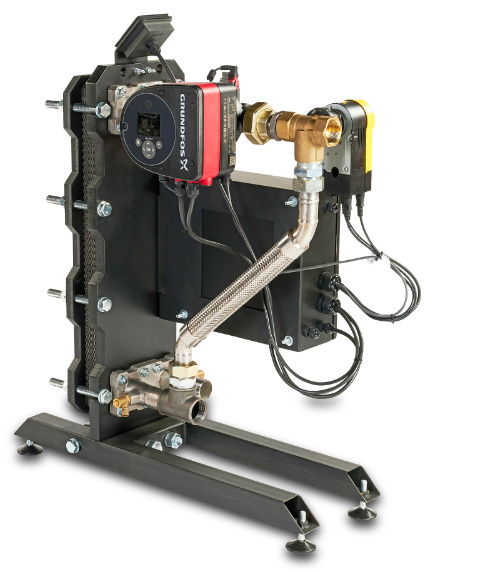

FlexEJ’s new range of PhexPak Packaged Plate Heat Exchangers bring efficiency, performance and control to commercial hot water and heating circuits.

The PhexPak packaged plate heat exchanger is designed and built at our factory in the UK and all standard range models are available for dispatch within 10 working days.

PRODUCT GUIDES

Plate Heat Exchangers

WHAT IS A PACKAGED PLATE HEAT EXCHANGER?

Packaged plate heat exchangers monitor and maintain a secondary temp setpoint..

OVERVIEW

A plate heat exchanger combined with additional specific temperature and flow control components.

Application

Instantaneous and semi-instantaneous DHW & LTHW, as required.

Rating

Heat load duty 50kW to1200kW. Temp range: 60°C to 100°C. Pressure rating: 10barg max.

WARRANTY

The PhexPak comes with up to a 3 Year warranty.

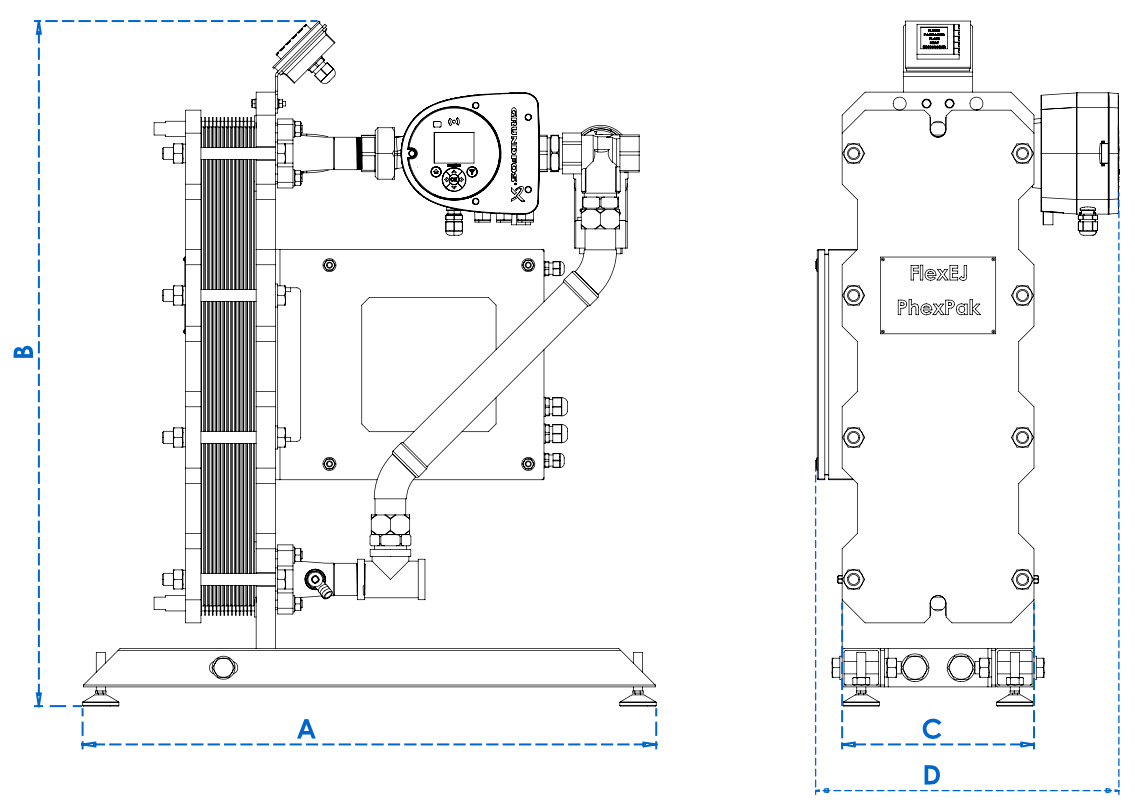

FlexEJ PhexPak Packaged Plate Heat Exchangers

| Heat load Duty (kW) | Secondary flow rate (l/s) | Dim A (mm) | Dim B (mm) | Dim C (mm) | Dim D (mm) |

|---|---|---|---|---|---|

| 100 | 0.48 | 745 | 890 | 250 | 395 |

| 200 | 0.96 | 745 | 890 | 250 | 395 |

| 300 | 1.44 | 745 | 920 | 250 | 515 |

| 400 | 1.93 | 745 | 920 | 250 | 515 |

| 500 | 2.41 | 745 | 960 | 315 | 560 |

| 600 | 2.98 | 745 | 960 | 315 | 560 |

| 700 | 3.37 | 745 | 960 | 315 | 560 |

| 800 | 3.85 | 745 | 960 | 315 | 560 |

| 900 | 4.33 | 745 | 960 | 315 | 560 |

| 1000 | 4.81 | 745 | 960 | 315 | 560 |

| 1100 | 5.30 | 745 | 960 | 315 | 560 |

| 1200 | 5.78 | 745 | 960 | 315 | 560 |

How does the PhexPak Packaged Plate Heat Exchanger work?

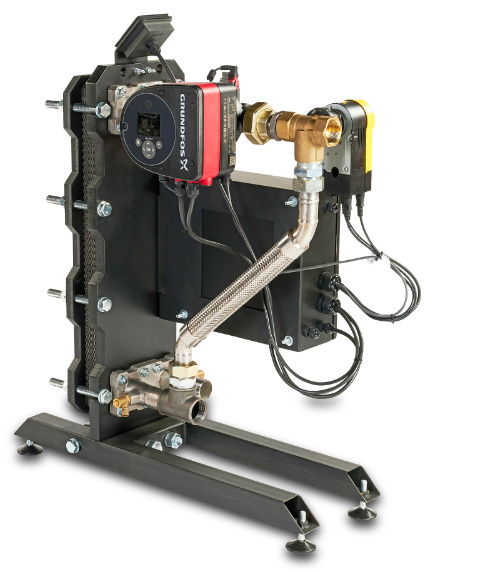

PhexPak features an intelligent control system allowing app-based operation from any smart device via Bluetooth connectivity. Standard operating functions via local interface. BMS connectivity via BACnet allows for full set-up and operation. Daisy chain functionality allows multiple units to be connected easily.

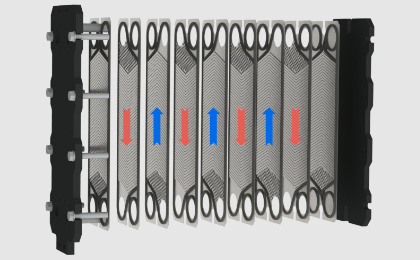

PhexPak features an intelligent control system allowing app-based operation from any smart device via Bluetooth connectivity. Standard operating functions via local interface. BMS connectivity via BACnet allows for full set-up and operation. Daisy chain functionality allows multiple units to be connected easily. The plate pack handles the heat transfer from the primary to the secondary. It does this by squeezing the flow of both circuits through alternating channels in the plates that run in opposing directions (counterflow). The secondary temperature is continuously monitored by a submerged sensor to ensure the setpoint is maintained and that deviations are recognised instantly.

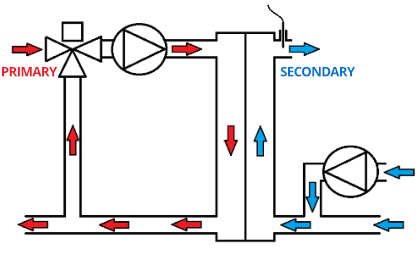

The plate pack handles the heat transfer from the primary to the secondary. It does this by squeezing the flow of both circuits through alternating channels in the plates that run in opposing directions (counterflow). The secondary temperature is continuously monitored by a submerged sensor to ensure the setpoint is maintained and that deviations are recognised instantly. There are often fluctuations in flow and temperature in a primary system due to changes in demand. When this occurs and there are deviations in temperature, recirculation is utilised to balance the primary flow in order to maintain the correct secondary setpoint.

There are often fluctuations in flow and temperature in a primary system due to changes in demand. When this occurs and there are deviations in temperature, recirculation is utilised to balance the primary flow in order to maintain the correct secondary setpoint. Water flow in the primary circuit is maintained and balanced via an intelligent variable curve pump. This pump overcomes the pressure drop within the heat exchanger and ensures no drop in flow when there is increased demand on the primary system elsewhere.

Water flow in the primary circuit is maintained and balanced via an intelligent variable curve pump. This pump overcomes the pressure drop within the heat exchanger and ensures no drop in flow when there is increased demand on the primary system elsewhere.

The PhexPak packaged plate heat exchangers also offer the system separation and pressure protection that comes with a standard plate heat exchanger when installed with an LTHW secondary system.

The PhexPak packaged plate heat exchangers also offer the system separation and pressure protection that comes with a standard plate heat exchanger when installed with an LTHW secondary system. Please call National Sales Manager Toby Stone on 07780 680870 or our specialist HVAC sales & support team on +44 (0) 1384 881188 or email us at sales@flexej.co.uk or use Live Chat on this web site – we are here to help, please get in touch.

Please call National Sales Manager Toby Stone on 07780 680870 or our specialist HVAC sales & support team on +44 (0) 1384 881188 or email us at sales@flexej.co.uk or use Live Chat on this web site – we are here to help, please get in touch.Introducing FlexEJ’s new PhexPak Packaged Plate Heat Exchangers

The FlexEJ PhexPak Packaged Plate Heat Exchanger range is designed to work across a vast range of applications, and across multiple sectors. Designed and manufactured in the UK, and utilising only the very best components, this product offers high quality, and real value for money.

PhexPak Applications

The FlexEJ PhexPak is primarily designed to monitor, balance, and maintain heat transfer between 2 circuits, whilst ensuring the desired setpoint is achieved. This makes it a particularly good option for commercial DHW supply, and a great alternative to typical calorifiers. The PhexPak can be used to supply DHW instantaneously, or semi-instantaneously when linked to a direct feed storage vessel. PhexPak can also be used on LTHW systems with varying primary flow temps to ensure the secondary circuit temp is maintained.

PhexPak Range Overview

PhexPak packaged plate heat exchangers cover a vast range of applications due to their flexibility. The standard range covers a heat load duty from 50kW to 1200kW, and offers a host of additional accessories to meet the requirements of the install. We can also bespoke design and build the PhexPak to meet your needs where the standard range isn’t a suitable fit.

PhexPak Features

Performance

- 50kW to 1200kW heat load duty

- Up to 5.78 l/s secondary flow @10°C-60°C DHW

Digital functionality

- Intelligent operation – linked by Bluetooth to any smart device

- Smart App for full application setup and control

- BACnet connectivity with Daisy Chain capability

- Local interface displaying:

– Set point

– Secondary flow temp

– Fault indicator

– On/Off - Built in manual reset hi-limit function

- Built in fault indicator function

Product information

- Single or twin head primary pump options (up to 600kW duty)

- Primary supply temp up to 100°C

- 3 port mixing valve with fast acting actuator

- 316 stainless steel exchanger plates

- EPDM gaskets

Optional extras

- Secondary Transfer pump

– Matched to secondary flow rate

– For use with storage / buffer vessel on semi-instantaneous DHW systems - Secondary Recirculation pump

– One size fits all

– Designed to assist recirculation with instantaneous DHW systems - Insulation jacket

| Heat load Duty (kW) | Secondary flow rate (l/s) | Dim A (mm) | Dim B (mm) | Dim C (mm) | Dim D (mm) |

|---|---|---|---|---|---|

| 100 | 0.48 | 745 | 890 | 250 | 395 |

| 200 | 0.96 | 745 | 890 | 250 | 395 |

| 300 | 1.44 | 745 | 920 | 250 | 515 |

| 400 | 1.93 | 745 | 920 | 250 | 515 |

| 500 | 2.41 | 745 | 960 | 315 | 560 |

| 600 | 2.98 | 745 | 960 | 315 | 560 |

| 700 | 3.37 | 745 | 960 | 315 | 560 |

| 800 | 3.85 | 745 | 960 | 315 | 560 |

| 900 | 4.33 | 745 | 960 | 315 | 560 |

| 1000 | 4.81 | 745 | 960 | 315 | 560 |

| 1100 | 5.30 | 745 | 960 | 315 | 560 |

| 1200 | 5.78 | 745 | 960 | 315 | 560 |

PhexPak Product Dimensions Diagram

Packaged Plate Heat Exchanger Sizing

Please refer to the dimensions table and diagram above to see the full range of heat load duties, flow rates and overall dimensions — as well as the summaries below for our 3 standard PhexPak modular sizes for DN32, DN40 and DN50 connections:

DN32 PhexPak

DN32 PhexPak

- Heat load duty up to 200kW

- Up to 0.96 l/s secondary flow rate (DHW @10°C – 60°C)

- Dim A : 745mm

- Dim B : 890mm

- Dim C : 250mm

- Dim D : 395mm

Please call us direct for advice or ask us to provide a quote and specification for your requirements.

DN40 PhexPak

DN40 PhexPak

- Heat load duty from 300kW to 400kW

- Up to 1.93 l/s secondary flow rate (DHW @10°C – 60°C)

- Dim A : 745mm

- Dim B : 920mm

- Dim C : 250mm

- Dim D : 515mm

Please call us direct for advice or ask us to provide a quote and specification for your requirements.

DN50 PhexPak

DN50 PhexPak

- Heat load duty from 500kW to 1200kW

- Up to 5.78 l/s secondary flow rate (DHW @10°C – 60°C)

- Dim A : 745mm

- Dim B : 960mm

- Dim C : 315mm

- Dim D : 560mm

Please call us direct for advice or ask us to provide a quote and specification for your requirements.

Your Specific Requirements

We understand that there are many different challenges and obstacles to overcome when installing plant room equipment, whether that’s newbuild or refurb. With that sometimes comes a necessity to adapt to unusual scenarios. The PhexPak is designed in a way that understands those needs, and allows for complete flexibility and adaptability. If you believe the standard range isn’t suitable for your needs, get in touch with our sales & support team and they can offer all the support you need to start designing a suitable PhexPak for your project.

Future Flexibility

Due to the unique modular design of the PhexPak, it’s versatile enough to meet the ever changing needs of any given project. If for instance, there was an increase in demand on a particular system or circuit due to building expansion or refurb, and that required a higher kW heat load duty and additional pump power, an upgrade could be completed on the PhexPak to meet those additional requirements..

Whatever your needs in terms of understanding the opportunities the PhexPak brings or the exact specification your installation needs, do please call Toby Stone direct on 07780 680870 — or please use the Get A Quote form out of hours.

Can't see what you want? Need help?

Call us. Or use Live Chat.

For instant advice. We can custom-design and engineer almost any expansion joint you need for delivery in the UK or worldwide. Call our expert team on +44 (0) 1384 881188 Or email us sales@flexej.co.uk

Frequently Asked Questions

A. Hot water requirements for commercial projects are typically calculated using CIBSE guidance to meet the required standards. We utilise BS EN806 and BS 8558 to help our customers understand their requirements and can provide suitable product options to meet those requirements.

A. In a word, yes. A packaged plate heat exchanger is a great replacement for a calorifier for the vast majority of applications.

A. Not entirely, but it will significantly reduce the risk if installed to supply DHW instantaneously due to the vastly reduced volume of water in the system when the storage element is removed.

A. Plate heat exchangers are one of the most efficient ways to transfer heat in the HVAC industry, in fact they are 99% efficient with only a 1% heat loss in most scenarios. Couple this with the most efficient pumps and control components available in today’s market and you have an unbeatable solution.

A. Packaged plate heat exchangers are typically installed freestanding in a plant room, and are connected via the 4 following connection points: Primary flow, Primary return, Secondary flow, and secondary return. Power is then supplied to the control panel and the unit is ready for commissioning and setup.

A. Packaged plate heat exchangers tend to cost more than standalone plate heat exchangers, but offer a wide range of benefits that a standalone plate heat exchanger simply can’t offer. They are also supplied with all the required pumps, valves and control components fitted to ensure optimum performance of the heat exchanger.

A. A calorifier is a storage buffer vessel that holds a body of water (most commonly DHW), and has an internal coil or similar heating element which circulates a primary heating circuit, designed to indirectly heat the body of water in the vessel.