MANUFACTURING

FlexEJ has full UK in-house design and manufacturing capabilities to EN, ASME and PED standards.

24hr Shipping

On all stock items ordered.

Mon-Thur by 2pm, 10am Fridays

Design & Manufacturing

Full in-house design & manufacture to EN / ASME / PED.

ISO14001 Accreditation

FlexEJ has an accredited Environmental Management System.

Design, Manufacturing & Special Projects

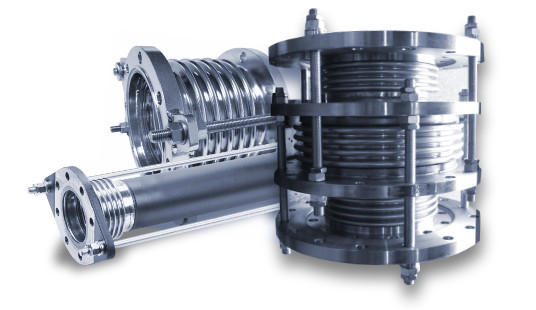

FlexEJ is a manufacturer. Working to industry recognised standards and the PED, we design and engineer complex expansion joints and pressure vessels as well as developing new products. In collaboration with our customers, we meet their specifications on build-to-order projects as well as providing innovative solutions where appropriate.

FlexEJ has developed robust in-house systems for controlling project documentation and manufacturing records which ensure final documentation is delivered within days of the physical items being complete.

Key design and manufacturing expertise

Product design, project delivery through to OEM partnership – FlexEJ have the skills and tools to deliver value:

Design – Metal Bellows Expansion

Manufacturing & Projects

DESIGN – METAL BELLOWS EXPANSION

Manufacturing & Projects

Metal bellows design is an iterative process. The task is to search for the optimum solution: rugged, long life bellows which can still provide the required movements at the specified pressure and temperature. The more we understand about your application, the closer to that optimum we will be able to get.

FlexEJ has developed and qualified its own integrated suite of tools for bellows design to EJMA10, component temperature modelling and restraint design for tie rods, hinges and gimbals.

These tools enable our design team to quickly calculate and optimise a new expansion joint based on your design specifications. This tool-set integrates with SolidWorks.

Overall design to B31.3 or EN13445 and PED as required.

Project Engineering and Documentation

Expansion & Vessels

PROJECT ENGINEERING & DOCUMENTATION

Control and Traceability

Being a manufacturer with a strong project engineering team allows us to work with our customers’ systems and requirements from the very earliest stages of the project though to successful completion.

Documentation and material control is achieved using a database which integrates together our ERP system with the engineering drawing and component details. This enables us to compile the manufacturing data book in real time as materials are received, welded or any NDT is carried out.

We are very well versed in project documentation, having worked with many large clients who require us to adhere to their own project specific formats and content.

OEM Partnership

Design, manufacture, stock, distribute

OEM PARTNERSHIP

Part of your team

We have a long and successful history of working with OEMs, some for over 16 years now, covering everything from the simplest metal hose to large pressure vessels.

FlexEJ is highly adaptable and willing to develop the processes required to support long term manufacturing partnerships; we understand what it takes to deliver value.

Our design team, experience and capability is at your disposal to bring high value products to the market quickly. By working closely together, we can ensure the design is optimised for manufacture in our facilities, minimising costs and improving lead times.

Can't see what you want? Need help?

Call us. Or use Live Chat.

For instant advice. We can custom-design and engineer almost any expansion joint you need for delivery in the UK or worldwide. Call our expert team on +44 (0) 1384 881188 Or email us sales@flexej.co.uk

Frequently Asked Questions

A. Yes, we can package the vessel with associated piping, valves, instrumentation and equipment, skid mounted or free standing. To view some examples of our past projects, go to the pressure vessels page and scroll down to the gallery. For technical assistance please contact us or use our Live Chat facility.

A. Yes, FlexEJ designs and manufactures engineered pressure vessels to PED, ASME 8, EN13445 and PD5500 as required – plus customer specifications. We can also manufacture to your design and drawing. For technical assistance contact us or use our Live Chat facility.

A. Yes, FlexEJ is accredited to ISO9001:2015 and ISO14001:2015. For sales assistance please contact us or use the Live Chat link on this page.

A. Yes, FlexEJ has full design capability for engineered metal expansion joints and can work to any recognised standard – typically EJMA, B31.3/Appendix X, EN14917 plus PED and/or other customer specifications. Engineered rubber expansion joints are typically designed to meet the FSA guidelines plus PED and/or other customer specifications For technical assistance please contact us or use the Live Help link on this page.

A. If you have any questions you would like to ask us directly please use LIVE CHAT or call us directly on 01384 881188 or use the CONTACT US form and we’ll get back you asap, usually within 24hrs, sooner if more urgent.

Please visit our full FAQ page to see all our frequently asked questions.