FlexEj’s DHW commercial buffer vessels

FlexEJ’s range of high grade, stainless steel, DHW buffer vessels.

24hr Shipping

On all stock items ordered.

Mon-Thur by 2pm, 10am Fridays

Design & Manufacturing

Full in-house design & manufacture to EN / ASME / PED.

ISO14001 Accreditation

FlexEJ has an accredited Environmental Management System.

DHW Commercial Buffer Vessels

PRODUCT GUIDES

BUFFER VESSELS

WHAT IS A DHW COMMERCIAL BUFFER VESSEL?

A QUICK OVERVIEW…

OVERVIEW

High-grade 316 stainless steel storage vessel offering increased capacity within a commercial hot water system.

Application

Hot water systems (DHW / HWS) supplied directly with Hot Water.

Rating

10 barg at 110°C.

WARRANTY

FlexEJ buffer vessels have a 5 year operating warranty.

How do Commercial Buffer Vessels work?

A buffer vessel is designed store hot water – it is not a “calorifier”, so not designed to heat the volume of water within it. The buffer vessel is thus designed to be supplied directly with hot water.

A buffer vessel is designed store hot water – it is not a “calorifier”, so not designed to heat the volume of water within it. The buffer vessel is thus designed to be supplied directly with hot water.

The buffer allows the hot feed rate to be less than the DHW draw rate for a period, the volume being chosen to be adequate for peak draw.

The hot water feed will be heated directly by a heat source or indirectly by a heat exchanger , such as the FlexEJ PhexPak Packaged Plate Heat Exchanger.

Buffer vessel connections are straight forward comprising:

Buffer vessel connections are straight forward comprising:

• Hot water flow and return

• Cold feed

• DHW draw off and DHW system return.

FlexEJ provide a full set of ancillary connections for :

FlexEJ provide a full set of ancillary connections for :

• TPRV (Pressure & Temperature Relief Valve)

• AAV (Automatic Air Vent)

• AVV (Automatic Vacuum Valve)

• Drain

• Immersion heater

• Temperature sensor/stat.

Standard range with nominal capacity of :

Standard range with nominal capacity of :

• 250l

• 500l

• 750l

• 1000l

FlexEJ install pipes in the buffer vessel to minimise unnecessary mixing within the vessel when DHW is being drawn off.

FlexEJ install pipes in the buffer vessel to minimise unnecessary mixing within the vessel when DHW is being drawn off.

This helps temperature stratification within the buffer and ensures the DHW drawn off is maintained at the highest available temperature.

Please call National Sales Manager Toby Stone on 07780 680870 or our specialist HVAC sales & support team on +44 (0) 1384 881188

Please call National Sales Manager Toby Stone on 07780 680870 or our specialist HVAC sales & support team on +44 (0) 1384 881188

Or email us at sales@flexej.co.uk or use Live Chat on this web site – we are here to help, please get in touch.

FlexEJ’s range of DHW Buffer Vessels

The FlexEJ Buffer Vessel range is designed to offer additional capacity and capability to any commercial hot water system. Designed and manufactured in the UK, entirely from 316 stainless steel, this product offers high quality, and real value for money.

The buffers complement our PhexPak packaged plate heat exchanger range, the PhexPak being an ideal source of hot water heated indirectly from any suitable heat source.

The standard range of buffer vessels are available in 4 nominal capacities; 250l, 500l, 750l, and 1000l. We can also bespoke design and manufacture buffer vessels to meet your needs where the standard range isn’t a suitable fit, or the capacity required is greater than 1000l.

How to size a DHW Commercial Buffer Vessel

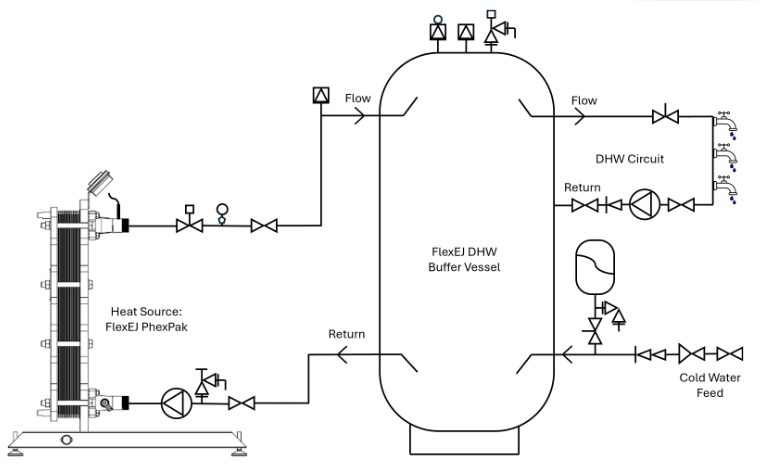

Below is a typical schematic of a buffer vessel based DHW system. The size of the buffer vessel(s) required is based on :

• Hot feed rate and rise time

• DHW maximum design draw rate

• Allowable DHW temperature variation

The hot feed rate depends directly on the kW size of the heat source and its availability. A heat source that is at times of DHW demand starting up from “cold” or is supplying other loads will require a larger buffer capacity to maintain DHW supply.

The maximum DHW draw rate is calculated according to the design standard adopted for the project. This is generally done by estimating the maximum probable concurrent usage given the type of building, numbers / types of outlet and predicated time based usage.

The size of heat source and buffer storage volume can the be optimised for both installed cost and operating energy consumption.

Typical installation only : Compliance with building regulations, water by-laws and any other applicable standards must be checked and adhered to prior to installation.

FlexEJ’s Commercial Buffer Vessels

250L to 1000L as standard – or bespoke

FlexEJ is a long established pressure equipment manufacturer based in the West Midlands. We design and manufacture buffer vessels in-house.

FlexEJ buffer vessels are dimensionally consistent and carefully constructed.

We have a long history of pressure vessel manufacture and can design and manufacture much larger buffer vessels to order. Let us know your requirements and we will be happy to help.

Buffer Vessel Insulation

Flexible, removeable, high performance

The insulation jackets we offer are constructed from silicon coated glass fibre cloth and ceramic fibre insulation.

This construction means that the jacket is not adhered to the buffer vessel – it is fully removable to aid inspection, upgrade and eventual recycling.

Our approach also allows us to offer insulation jackets tailored to specific performance requirements as a special.

DHW Systems and Buffer Vessels

The FlexEJ commercial heating product range combines together to provide a complete DHW system.

Contact us for help and advice, we will be pleased to discuss your project and alternative solutions.

Can't see what you want? Need help?

Call us. Or use Live Chat.

For instant advice. We can custom-design and engineer almost any expansion joint you need for delivery in the UK or worldwide. Call our expert team on +44 (0) 1384 881188 Or email us sales@flexej.co.uk

Frequently Asked Questions

A. A buffer vessel is a storage tank – in the case of a DHW system it stores hot water. This water is immediately available to the DHW consumers and eliminates any delay in the heat source coming on line or up to temperature.

A. That depends on the heat source you have and the demand on the DHW draw off. If the heat source is constantly available, always at the correct temperature and capable of supplying the peak demand of DHW then no, you don’t need a buffer vessel. In a practical system it would be expensive and inefficient to meet those criteria so a buffer vessel is normally included.

A. This depends on the capability and availability of the heat source and the peak demand of the DHW system. The correct buffer vessel volume allows an economic and energy efficient design to be achieved.

A. We would recommend using the FlexEJ PhexPak as it provides isolation and control in one convenient package.

A. The buffer vessels do not have specific approval number but are suitable for potable water and meets the needs of a Water Regulation 4 material approval due to being 100% 316 stainless steel.

A. Yes, all of our standard buffer vessels are supplied with an industry standard 2¼” boss to fit an immersion heater.

A. Yes, there is a 2½” connection on top to accommodate up to the largest size commercial TPRVs.

A. Yes we can. Do see our new DHW System Valves page for compatible valves or call our expert team for assistance with selection with this or anything in FlexEJ’s buffer vessels and PhexPak packaged plate heat exchanger ranges.